Get A Quote

For more information. Please complete this form.

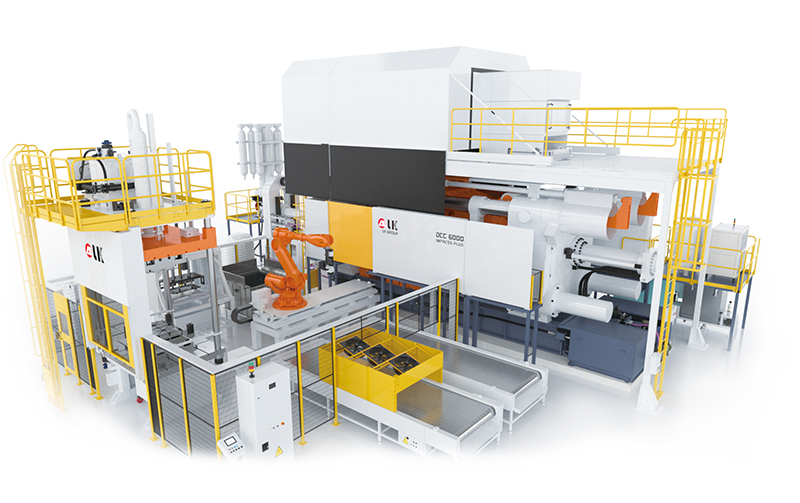

LK Machinery India Pvt. Ltd. is India's leading manufacturer of die casting machines. We offer world-class customer service and support to all our customers.

Our die casting machine manufacturers and suppliers have been in this business since 1979 and are committed to providing high-quality products and services that meet our customers’ needs.

We provide a range of die casting Machines in India that can be used for numerous applications across the globe. Our team of experts can help you find the right machine for your needs.